Recirculation cooler DL30-300CE

1 phase, 220-240V/50Hz

Refrigerant: R410A

Temperature range: -30℃~5℃*

Bath liquid filling: 10L

Pump flow rate: 20L / min

Temperature stability: ±2℃

Pump pressure: 0.4bar

Hose connection size: 1/2''

*The working temperature range should be≤ RT-5 *C.

These models of chillers are used to ensure constant low-temperature environment for chemical, biological and physical experiments that need to be carried out at low temperatures. They are mainly used in medicine and health care, food industry, chemical industry and for educational purposes in research institutes.

Advantages

- It is used in chemistry and biology as a fermenter, a vessel for chemical synthesis, etc.

- Equipped with a world-famous brand compressor, it provides low noise, high reliability, stable operation and a long service life.

- A completely closed circulation system prevents evaporation or contamination of the liquid in the bath.

- Filters built into the hoses prevent clogging.

- Eco-friendly refrigerant without freon complies with international standards.

- Compact design with beautiful appearance.

- Liquid level indicator allows you to monitor the amount of refrigerant remaining in the bath.

- Removable side panels for quick and easy cleaning Sources and maintenance international standards.

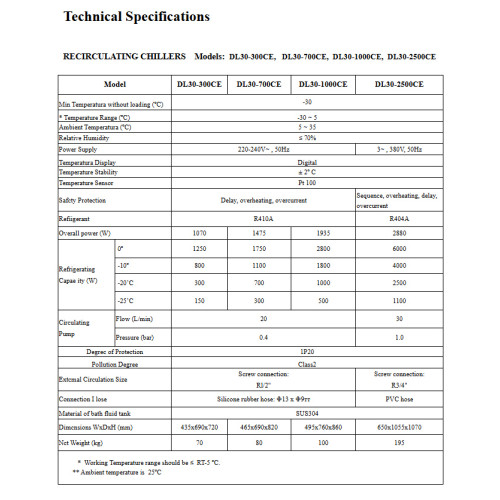

** Unique technical characteristics of each model are given in the technical characteristics table of each model, as well as in the visual comparison table of all four models of chillers of the DL series, available at our warehouse

- Link

- Price

- Availability

- Quantity

- DL30-300CE

- 3,124.00€

- 5

-

-

Recirculation Cooler DL30-300CE

Last week a colleague was running a vacuum distillation overnight, and by morning the condenser had lost efficiency because his ice bath had melted hours earlier. Recirculation coolers eliminate this problem entirely—the DL30-300CE maintains -30°C to 5°C continuously without anyone babysitting frozen water or dry ice. When you need sub-zero cooling that doesn't quit halfway through a synthesis or solvent recovery, compressor-based chillers become non-negotiable equipment.

Below-Ambient Temperature Management for Condenser Coils

The 300W cooling capacity handles typical rotary evaporator loads without temperature drift during extended runs. Pair it with a Rotary evaporator R-1020CE for methanol or ethanol recovery—set the chiller to -10°C and watch condensation rates improve dramatically compared to tap water cooling. The 20 L/min pump flow prevents thermal gradients across your condenser coil, which matters because uneven cooling creates hot spots where vapor escapes uncondensed. That 10-liter reservoir cycles completely every 30 seconds, maintaining consistent thermal transfer even when distillation rates spike.

Optimizing Vacuum Distillation Efficiency

- Acetone and low-boiling solvents: Running a Rotary evaporator R-1050CE with acetone? Set -5°C to capture vapors efficiently without risking freeze-ups in your condenser lines

- High-throughput operations: The DL30-300CE works for moderate loads, but if you're processing larger batches, compare the Recirculating chiller DL30-700CE or Recirculating chiller DL30-1000CE for higher wattage capacity

- Smaller setups: Labs with limited bench space or lower cooling demands should evaluate the Recirculating chiller DLSB-5/20A as an alternative

Recirculating Cooling System Architecture

Digital temperature controls beat analog dials because you can replicate exact conditions between experiments—critical when validating methods or training new staff. The compressor cycles based on coolant temperature rather than running constantly, which cuts electricity costs during steady-state operation. At 70kg and 435x690x720mm dimensions, plan for permanent installation rather than moving it around. Keep 15cm clearance on all ventilated sides—blocking intake vents causes compressor overheating and shortened lifespan. Check coolant weekly during heavy use, and flush quarterly if using tap water instead of distilled to prevent mineral buildup in the pump housing.