Recirculating chiller DL30-700CE

Minimum temperature without loading (ºC) : -30

Temperature stability : ±2°C

Temperature range : from -30°C to ~5*

Capacity Pump : 20 l/min

Pump pressure : 0.4 bar

Power supply : 220-240, 50Hz.

Bath liquid filling: 17L

*The operating temperature range should be ≤ RT-5 *C

This model of refrigerator is generally used to provide a constant low-temperature environment for chemical, biological and physical experiments that need to be carried out at low temperatures. It is mainly used in medical and health care, food industry, chemical industry and for teaching purposes in research institutes.

Advantages

• Applications in chemistry

and biology as a fermenter, chemical synthesis vessel, etc.

• Equipped with a world-famous

brand compressor, it provides low noise, high reliability, stable operation and

long service life.

• A completely closed

circulation system prevents evaporation or contamination of the liquid in the

bath.

• Filters built into the hoses

help prevent clogging.

• Environmentally friendly

refrigerant without CFCs meets international standards.

• Compact design with

beautiful appearance.

• The liquid level indicator

allows you to monitor the volume of coolant remaining in the bath.

• The liquid pressure in

the bath can be measured using a pressure gauge, which is attached near the

liquid outlet.

• Removable side panels for quick and easy cleaning and

maintenance

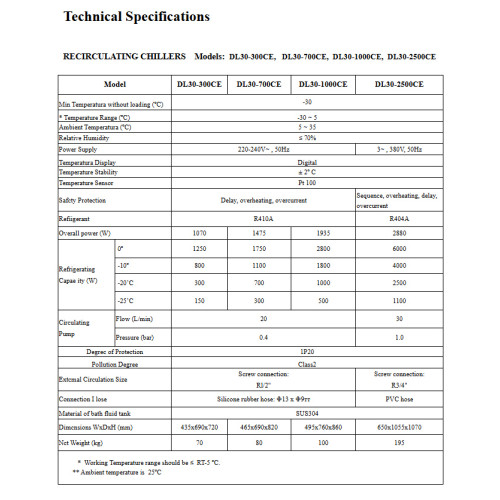

**The technical

specifications of each model are given in the table of technical specifications

of each model, as well as in the table of visual comparison of all four models

of DL series refrigerators we have in stock

- Link

- Price

- Availability

- Quantity

- DL30-700CE

- 3,418.00€

- 3

-

-

Thermal Management for Full-Capacity Rotary Evaporation

Running a rotary evaporator at maximum throughput generates serious heat. Last summer, our synthesis team kept losing dichloromethane vapors during back-to-back distillations—the problem wasn't the rotovap, it was the undersized chiller struggling to maintain condenser temperature. Once we switched to the DL30-700CE, those losses stopped.

Pairing the DL30-700CE with High-Volume Rotovaps

The Rotary evaporator R-1020CE and Rotary evaporator R-1050CE both demand chillers that can handle sustained thermal loads without temperature drift. At 700W cooling capacity, this unit sits between the Recirculating chiller DLSB-5/20A at 200W (fine for occasional use) and the Recirculating chiller DL30-1000CE for industrial-scale operations. Here's what that means practically:

- 20 liters per minute flow rate pushes coolant through large condenser coils fast enough to prevent warm spots that let solvents escape

- 2 bar pressure maintains circulation even with 3-meter tubing runs, so you can position the chiller outside the fume hood

- R404A refrigerant reaches -30°C minimum, capturing low-boiling solvents like diethyl ether that warmer systems miss

Serious Cooling Power for Continuous Processing

We run our Rotary evaporator R-1020CE six hours daily processing reaction mixtures. The ±2°C temperature stability prevents the thermal cycling that causes inconsistent distillation rates—your bath stays at setpoint instead of swinging 5-8°C like cheaper units. The 80kg thermal mass acts as a buffer when you start a fresh distillation and suddenly dump heat into the system.

Compare this to the Recirculation cooler DL30-300CE at 300W: adequate for a single small rotovap, but it struggles when you're removing 500mL of solvent per hour from heat-sensitive compounds. The 700W capacity handles three simultaneous distillations or one large-scale run without temperature creep.

Heat Dissipation in Extended Operations

Closed-loop recirculation saves thousands of liters monthly compared to tap water condensers. Our lab calculated 3,200 liters saved per month running two rotovaps daily. The system maintains consistent thermal properties year-round—tap water varies 10-15°C seasonally, affecting your condenser performance.

Mount the 465x690x820mm unit on a reinforced cart (it weighs 80kg) and run it on a dedicated 220-240V circuit. The flow capacity supports daisy-chaining two instruments or connecting jacketed glassware alongside your primary rotovap. For reflux condensers on vacuum distillations, that -30°C capability prevents solvent loss that costs more than the chiller itself.