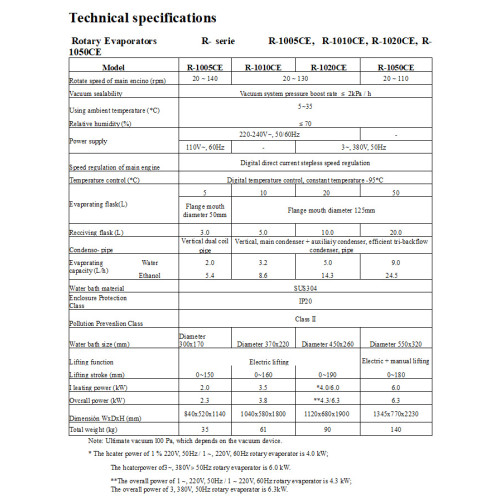

Rotary evaporator R-1050CE

- 3 ~ 380V/50Hz

- Evaporating flask: 50L*1

- Original flask: 20L*1

- Ware bath: ambient ~ 99℃

- Rotation speed: 20 ~ 110 rpm

- Motor power: 250W

- Motorized lifter: 0~180mm

- Water bath material:SUS304

- Electric and manual lift

Distillation dough purification equipment rotates and forms a thin film under negative pressure condition by heating, effectively evaporates and then condenses and collects the solvent for purification and separation.

Brief introduction:

1. Rotary evaporator (or rotary evaporator) is a device used in chemical laboratories to efficiently and gently remove solvents from samples by evaporation.

2. Large capacity, large diameter rotary evaporator flask, evaporation area, vacuum water bath with rotating heating edge, diffusion solution evaporation efficiency can be used for biological, pharmaceutical, chemical, food and other production fields.

- Link

- Price

- Availability

- Quantity

- R-1050CE

- 6,811.00€

- 4

-

-

Continuous Three-Shift Operation with the R-1050CE

When your pilot plant runs three shifts and downtime costs thousands per hour, you need equipment that matches your scale. I watched a pharmaceutical QC lab switch from running five Rotary evaporator R-1020CE units simultaneously to a single R-1050CE, and their throughput actually increased.

That 50-liter evaporating flask capacity isn't just a bigger number—it transforms how you approach batch processing. The receiving flask holds 30 liters, which means you're processing volumes that would take an entire day with smaller units. One organic synthesis lab I know uses theirs for recovering dichloromethane from extraction waste, reclaiming about 45 liters per run.

Industrial-Grade Durability for Round-the-Clock Production

- Stainless steel frame and borosilicate glass handle corrosive solvent vapors without degradation

- 140kg weight provides stability during high-speed rotation with full flask loads

- Dimensions of 1345x770x2230mm require dedicated floor space but eliminate vibration issues

- 380V, 50Hz power supply delivers consistent motor performance under heavy loads

The construction quality becomes obvious during month-long campaigns. Where smaller units might need bearing maintenance after extended runs, the R-1050CE's industrial-grade components just keep spinning. Pairing it with a Recirculating chiller DL30-700CE or Recirculation cooler DL30-300CE extends your operational window—a colleague running terpene distillations keeps his condenser at -10°C year-round, regardless of summer heat.

Minimizing Downtime in High-Stakes Pilot Plants

Rotation speed ranges from 20 to 110 rpm, giving you precise control over surface area renewal. At lower speeds, you're handling viscous botanical extracts without splashing. Crank it up to 110 rpm for ethanol recovery, and the thin film formation accelerates evaporation dramatically.

Vacuum tightness specifications show pressure increase rates ≤2 kPa/h, which matters when you're distilling heat-sensitive compounds. A research group working with natural product isolates told me they maintain 20 mbar for six-hour runs without pump cycling, protecting their temperature-sensitive alkaloids from thermal decomposition.

Performance Metrics for Demanding Environments

Operating between 5°C and 35°C ambient, you'll want serious cooling support. The Recirculating chiller DL30-1000CE handles the heat load when you're running multiple consecutive batches, while the Recirculating chiller DLSB-5/20A works for lighter-duty applications.

Pro tip: Clean all glassware joints and seals after each use—residual material breaks that vacuum seal faster than anything else. Check the vacuum system weekly during heavy use periods, and you'll avoid the frustration of mysterious pressure creep mid-distillation. The 125mm flange opening makes cleaning easier than you'd expect for a unit this size.

Leave a review about product

Sign up to our newsletter to get the latest news and updates about our products.