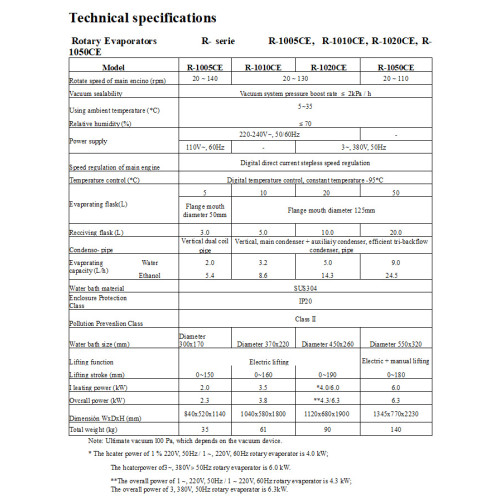

Rotary evaporator R-1020CE

- 3~380V/50Hz

- Evaporation flask: 20L*1

- Receiving flask: 10L*1

- Ware bath: Environment ~ 95℃

- Rotation speed: 20 ~ 130 rpm

- Motor Power: 250W

- Motorized Lift: 0~190mm

- Water Bath Material: SUS304

Equipment for cleaning distillation test rotates and forms thin film in conditions negative pressure by heating, effectively evaporates, and then condenses and collects solvent for cleanup and Partitions.

Brief Introduction :

1. Rotary evaporator (or rotary evaporator) - is device, used in chemical laboratories for efficient and lean removal solvents from samples by evaporation.

- Link

- Price

- Availability

- Quantity

- R-1020CE

- 4,984.00€

- 4

-

-

Scaling Up Extraction Operations with the R-1020CE

When your pilot-scale botanical extraction suddenly doubles in volume and you're scheduling rotovap time like it's an MRI machine, something needs to change. A hemp processing lab I visited last quarter was running two shifts on their 10-liter units until they brought in the R-1020CE. The 20-liter evaporating flask handles what used to require three sequential runs, and their weekend overtime basically disappeared.

High-Capacity Evaporation for Pilot-Scale Workflows

The system runs rotation speeds from 20 to 130 rpm, which matters more than you'd think when you're concentrating plant extracts that foam unpredictably. I keep mine around 65 rpm for ethanol recovery from winterized cannabis oil, but drop to 40 rpm when processing saponin-rich extracts that turn into foam volcanoes above 50 rpm. The 30-liter receiving flask gives you breathing room during long distillations—I've recovered 18 liters of methanol in a single run without stopping to empty the collection flask.

The motorized lift responds in under three seconds when vacuum drops unexpectedly. Last Tuesday, a cracked seal caused pressure loss mid-evaporation, and hitting the emergency lift prevented my sample from sucking back into the condenser. Small thing, but it saved four hours of prep work. The digital PID controller holds bath temperature within ±1°C, which becomes critical when you're working near the decomposition threshold of heat-sensitive alkaloids.

Consolidating Multiple Rotovaps into One System

- Brushless DC motor: Runs quietly enough to hold a conversation next to it, unlike the older belt-driven units that sound like washing machines

- Imported frequency converter: Speed adjustments are smooth without the jerky acceleration that can disrupt delicate emulsions

- Programmable memory: Save your standard ethanol recovery parameters (78°C bath, 90 rpm, 100 mbar) and recall them in ten seconds for the next batch

- GG-17 double coil condenser: Vertical configuration with enough surface area to handle aggressive evaporation rates without vapor breakthrough

Pair it with the Recirculating chiller DLSB-5/20A for standard organic solvent work, or step up to the Recirculation cooler DL30-300CE when you're pushing high vapor loads in summer without building air conditioning. For labs running continuous operations, the Recirculating chiller DL30-700CE or Recirculating chiller DL30-1000CE provide the cooling capacity to maintain condenser efficiency during back-to-back runs without temperature drift.

Technical Specifications and Throughput Capabilities

The borosilicate glass construction handles chlorinated solvents, acids, and bases without degradation. Stainless steel framework supports the 90kg total system weight without flexing, which prevents the slow misalignment issues that plague lighter frames after a year of use. If you're currently maxing out a 10-liter system daily, the R-1020CE doubles your throughput without requiring additional floor space or electrical upgrades beyond standard 220V service.

For operations that have outgrown even 20-liter capacity, the Rotary evaporator R-1050CE scales to 50 liters for production environments, but most R&D labs find the R-1020CE hits the capacity sweet spot between bench-scale development and pre-production batches. The control interface stays consistent across the line, so operators familiar with smaller units adapt within a single training session.

Leave a review about product

Sign up to our newsletter to get the latest news and updates about our products.