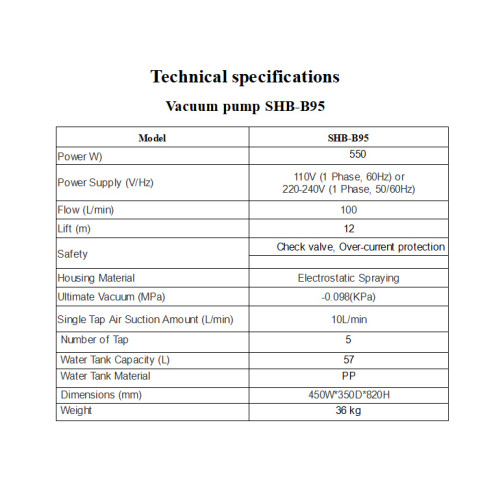

Vacuum pump SHB-B95

Maximum vacuum: 0.098 MPa

Extraction volume of one head: 10 l/min

Capacity tank: 57 L

Circulation flow rate: 100L/min

Pump head: 12m

Features:

Water circulating vacuum pump adopts circulating water as the working fluid to generate negative pressure liquid jet. It can provide negative pressure for the processes of evaporation, distillation, crystallization, drying, sublimation, pressure reducing filtration and so on, especially suitable for laboratories and small testing in industries such as universities and colleges, scientific research institutes, chemical industry, pharmaceuticals, biochemistry, food industry, agricultural machinery, biological engineering.

1. It is widely used in research experiments, small-scale testing and small-scale production with the processes of evaporation, distillation, crystallization, drying, sublimation, pressure-reducing filtration.

2. The working principle is the same as that of the desktop vacuum pump.

3. Compared with the desktop vacuum pump, larger suction air volume can meet the requirement of negative pressure with large suction air volume.

4. Five taps can be used separately or in parallel. The five-way adapter can connect five valves to increase the amount of air intake, which can meet the experimental requirements large-scale rotary evaporator or reactor.

5. The motor is supplied by famous manufacturer with fluororubber seal, which can avoid the penetration of corrosive gas.

6. The water tank is made of polyvinyl chloride (PVC). The body is made of carbon steel and the surface is electrostatic sprayed.

7. Copper ejector; Tee, check valve and suction pipe are made of polypropylene.

8. Pump body and impeller are made of 304 stainless steel.

- Link

- Price

- Availability

- Quantity

- SHB-B95

- 1,570.00€

- 8

-

-

Continuous Vacuum Performance with the SHB-B95 Water-Circulating System

Running rotary evaporators or filtration manifolds for hours at a time means you need vacuum that doesn't quit halfway through a distillation run. The SHB-B95 uses water circulation instead of oil to generate vacuum, so you're not worrying about oil mist contaminating your samples or scheduling maintenance around oil changes. With 100 L/min flow rate and five independent vacuum taps at 10 L/min each, you can run multiple pieces of equipment simultaneously—something you'll need when your TOPT-3L jacketed glass reactor (double glass reactor) and a rotovap are both pulling vacuum during synthesis work.

Built for Daily Rotary Evaporator and Filtration Operations

The five-tap design matters more than you'd think. Each tap delivers 10 L/min independently, which means you can connect a TOPT-1L Glass Jacketed Reactor (Double glass reactor) on one line while running vacuum filtration on another without pressure drops affecting either operation. The 57-liter water reservoir gives you 4-6 hours of continuous runtime before refilling, depending on ambient temperature and vacuum load. Compare that to the Vacuum pump SHB-III, which has a smaller tank and lower flow capacity—the B95 handles larger reactor volumes like the Glass Jacketed Reactor (Double Glass Reactor) TOPT-5L without struggling to maintain vacuum depth.

Water Recirculation Design for Sustainable Lab Use

- No oil contamination: Water-based vacuum generation eliminates cross-contamination risks when switching between different chemical processes

- Lower operating costs: No oil purchases, no disposal fees, no filter replacements every few months

- Quieter operation: The 550W motor runs at lower noise levels than oil pumps of equivalent capacity

- Temperature stability: Pair with Cooling circulator Chiller LX-0400 when working in warm labs to maintain consistent water temperature and vacuum performance

The anti-corrosion construction uses stainless steel internals and electrostatic-sprayed housing. When you're pulling vacuum on acidic distillations or alkaline filtrations, corrosion resistance directly affects pump lifespan. Expect 3-5 years of daily use before major component replacement, versus 1-2 years with poorly-protected pumps.

Reliable Vacuum Generation for Demanding Applications

Ultimate vacuum reaches 0.098 MPa (approximately 735 mmHg), which covers most lab vacuum needs from gentle solvent removal at 40°C to aggressive distillations at reduced pressure. The adjustable vacuum control lets you set specific pressures for sensitive compounds that decompose under deep vacuum—critical when working with natural product extractions or heat-sensitive intermediates in your jacketed reactor. Available in 110V (60Hz) or 220-240V (50/60Hz) configurations. Dimensions of 450 x 350 x 820 mm and 36 kg weight mean it fits under standard benches but stays stable during operation without walking across the floor.