Glass reactor GRL-10CE

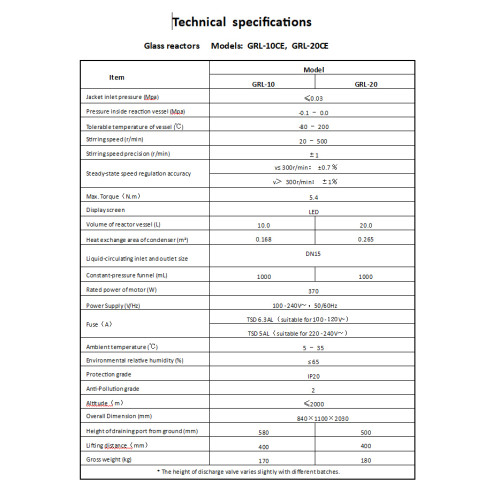

Reactor volume: 10 l

Jacket volume: 8 liters

Material: Borosilicate glass 3.3

Temperature range: from -80°C to 200°C

Stirring speed: from 20 to 500 rpm

Nominal pressure:from -0.1 MPa to 0.0 MPa

Jacket pressure:≤ 0.3 MPa

BLDC Motor: 370W

Controller: DSC350

Power supply: 100 - 240 V, 50/60 Hz

Overall dimensions: 840×1100×2030

Weight (kg): 48 kg

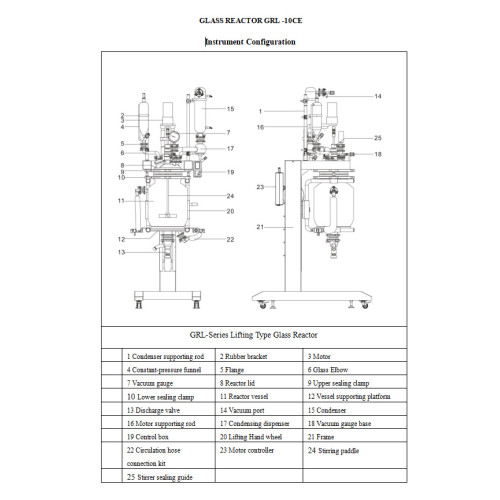

The GRL-10 glass reactor is easy to lift and lower.

You can easily disassemble the GRL-10 glass reactor.

120° rotation allows you to conveniently add solvents.

You can use the GRL-10 glass reactor in a variety of applications, from chemical to organic synthesis.

- Link

- Price

- Availability

- Quantity

- GRL-10CE

- 7,389.00€

- 2

-

-

Glass Reactor GRL-10CE: Pilot-Scale Chemical Synthesis Workhorse

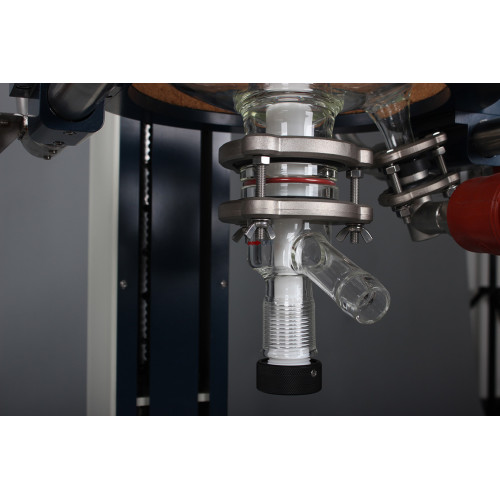

When you're scaling up from benchtop rotary evaporators like the Rotary evaporator R-1020CE to pilot-scale synthesis, the GRL-10CE becomes your workhorse. Last month, our organic chemistry group ran a three-day Grignard reaction at -15°C, and watching those reagents mix through the crystal-clear borosilicate walls while the Recirculating chiller DL30-700CE maintained precise jacket temperature made troubleshooting so much easier than staring at a metal vessel with just a thermocouple reading.

Transitioning from Benchtop to Pilot-Scale Chemical Synthesis

The 10-liter capacity hits that sweet spot between lab-scale work and production demands. You're not stuck doing twenty batches in a 1-liter flask, but you're also not committing to massive equipment if your fume hood can't accommodate the extra height. At 2030mm tall with the condenser assembly, this unit fits standard laboratory spaces while giving you enough volume for meaningful scale-up data. Compare this to the Rotary evaporator R-1050CE which maxes out at 50-liter evaporation flask capacity but lacks the reaction control you need for multi-step synthesis.

10-Liter Reaction Vessel for Process Development

Borosilicate 3.3 glass handles thermal shock that would crack standard glassware. We've gone from reflux at 180°C to ice-bath quenching without issues, though I wouldn't recommend making that a habit. Chemical visibility matters more than you'd think—spotting precipitate formation, color changes, or phase separation in real-time beats waiting for samples. When running heterogeneous catalysis reactions, you can actually see the catalyst bed behavior and adjust stirring speed between 20-500 rpm accordingly.

Scaling Up Beyond Rotary Evaporator Capabilities

The jacketed design circulates heating or cooling fluid through the outer wall, giving you temperature control from -80°C to 200°C depending on your circulator choice. For exothermic reactions where heat removal becomes critical, pair it with the Recirculation cooler DL30-300CE for moderate cooling needs or upgrade to the Recirculating chiller DLSB-5/20A when you need deep-freeze temperatures for organometallic chemistry. Unlike the Rotary evaporator R-1020CE which excels at post-reaction solvent removal, the GRL-10CE gives you active control during synthesis itself—think reflux condensers, addition funnels, and continuous stirring under controlled atmosphere.

Glass Reactor Design for Safe Chemical Processing

- Reflux synthesis: Standard organic preparations where you need extended heating under solvent reflux conditions

- Vacuum distillation: Operating range from -0.1 MPa lets you pull vacuum for solvent stripping

- Crystallization studies: Controlled cooling through the jacket produces reproducible crystal morphology

- Extraction processes: Continuous liquid-liquid extraction setups with real-time phase monitoring

The pressure relief valve isn't just regulatory compliance—it's saved us twice when exothermic runaway reactions generated unexpected gas evolution. At 170 kg gross weight, this reactor isn't going anywhere once installed, which beats the anxiety of watching smaller setups vibrate across benchtops during vigorous stirring.

Leave a review about product

Sign up to our newsletter to get the latest news and updates about our products.