Glass Jacketed Reactor with cover lift and body turn function TOPR-20L

Reactor volume : 20 liters

Pressure : up to 0.03 MPa

Temperature range : from -80 ° C to 200 ° C

Material : borosilicate glass

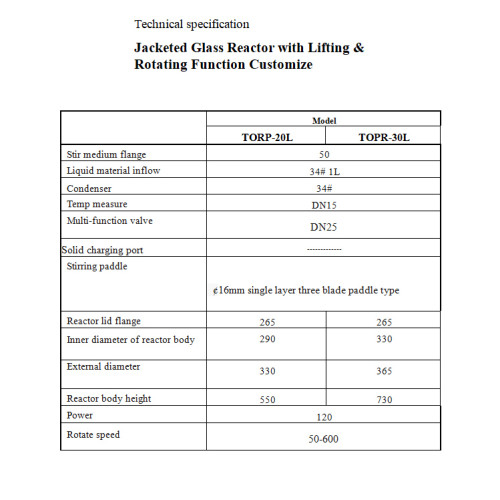

Stirring speed : from 50 to 600 rpm

Lid lifting mechanism : manual

Housing rotation function : 120 degree rotation capability

***No N2 gas inlet and 24# spare hole for lid (due to insufficient space).

Jacket glass reactor with lid lifting and body rotating function is a type of laboratory equipment used in chemical and pharmaceutical research and production. Glass reactor with lifting and rotating function is easy to use and clean. Glass interface flange seal eliminates the need for vacuum lubrication. The reactor body is made of borosilicate glass, which provides excellent chemical resistance and visibility of the contents. The reactor has a jacket design that allows temperature control by circulating heating or cooling fluids around the main body.

Used for distillation, crystallization, extraction, as well as for various chemical reactions requiring precise temperature control.

- Link

- Price

- Availability

- Quantity

- TOPR-20L

- 12,643.00€

- 1

-

-

Hydraulic Cover and Swivel Technology for 20-Liter Glass Reactors

Running multi-hour reflux reactions or air-sensitive organometallic chemistry at 20L scale gets exhausting when you're wrestling with heavy glass lids and trying to reach that back-side addition port. The TOPR-20L eliminates the awkward gymnastics through hydraulic cover lifting and a 360-degree rotating base—two features you won't find on the standard Glass Jacketed Reactor (Double Glass Reactor) TOPT-20L that stays locked in one position.

Built from 3.3 borosilicate glass with jacket circulation supporting -80°C to 200°C, the system holds ±0.5°C stability during exothermic polymerizations and cryogenic Grignard additions. The 90W overhead stirrer runs 50-600 rpm with PTFE anchor blades handling viscosities up to 10,000 cP, while vacuum capability down to 0.03 MPa enables solvent stripping under reduced pressure.

Automated Lifting System Reduces Manual Handling

Hydraulic assist raises the 8kg glass lid assembly through 400mm vertical travel without you hoisting it by hand. Pneumatic dampers control descent at 15mm/sec for smooth sealing against the PTFE gasket. When you're working with pyrophoric reagents or keeping everything under inert atmosphere through your Schlenk line, single-handed operation makes a real difference. Labs scaling up from the Glass Jacketed Reactor (Double Glass Reactor) TOPT-10L immediately notice the strain reduction—no more dropped lids or back injuries during 12-hour synthesis runs. The Glass Jacketed Reactor with Lid Lift and Body Rotation Function TOPR-30L offers 500mm lift clearance if you're running taller overhead condensers.

Rotating Base for Convenient Maintenance Access

Ball-bearing swivel base rotates the entire jacketed vessel without disconnecting circulation hoses or thermocouple probes. Indexed locking positions at 90-degree intervals let you:

- Face the reactor forward during active monitoring

- Rotate 90 degrees to access sidearm addition funnels

- Turn 180 degrees to expose the drain valve for product transfer

- Inspect internal coatings or precipitate buildup around the full circumference

Cleaning between batches becomes straightforward—rotate the vessel to scrub all interior surfaces without contorting around fixed frames. The standard Glass Jacketed Reactor (Double Glass Reactor) TOPT-50L requires partial disassembly for thorough decontamination, which adds hours to turnaround time in GMP environments.

Operator-Friendly Features for Scale-Up Chemistry

Integrated PT100 RTD probes track jacket inlet/outlet differential while the overhead display shows real-time torque values—critical for catching precipitation onset or gelation before your stirrer stalls. The 220V/50Hz control cabinet includes PID temperature regulation and programmable stirring profiles. Discharge valve positioning 45mm above vessel bottom prevents PTFE bearing contamination during product recovery.

Analytical workflows coupling synthesis with immediate characterization benefit from rapid sample access—the hydraulic lid gets your product to the Agilent 7200 QTOF GC-MS with 7693 Autosampler within 3 minutes of reaction completion. Labs running process development find the TOPR-20L bridges benchtop Glass Jacketed Reactor (Double Glass Reactor) TOPT-10L work to pilot-scale operations while still fitting under fume hoods.