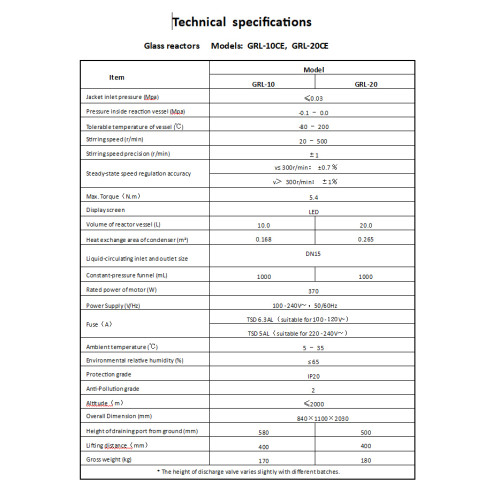

Glass reactor GRL-20CE

Vessel volume: 20 l

Jacket volume: 9 liters

Material: Borosilicate glass

Temperature range: from -80°C to 200°C

Stirring speed: from 20 to 500 rpm

Nominal pressure: from -0.1 MPa to 0.0 MPa

Jacket pressure:≤ 0.3 MPa

Weight: 67 kg

BLDC Motor: 370 W Controller: DSC350

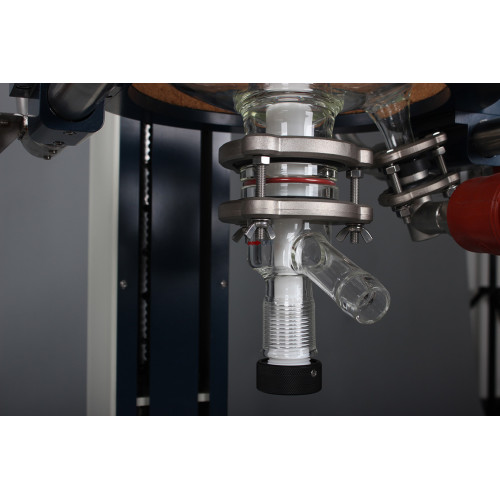

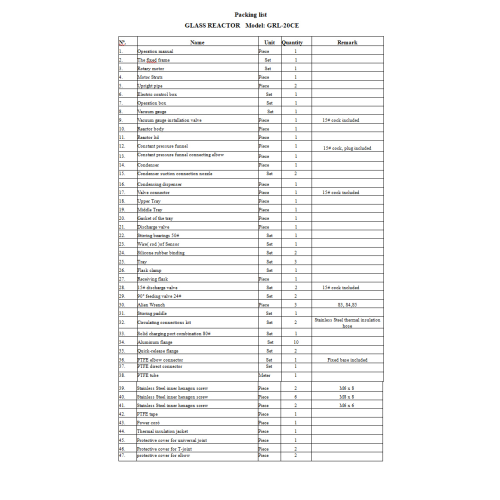

Power supply: 100 - 240 V, 50/60 Hz Overall dimensions Gross weight (kg): 180 Glass reactor GRL-20CE is a modern laboratory equipment designed for carrying out chemical reactions and processes that require precise control and observation. This reactor is made of high-quality borosilicate glass, which has excellent chemical and thermal stability, making it ideal for a wide range of laboratory applications. Its transparent design allows reactions to be easily monitored, giving researchers the ability to observe and adjust conditions as needed. The GRL-20CE is equipped with advanced features to improve efficiency and safety, making it an indispensable tool for R&D-focused laboratories. The GRL-20CE glass reactor is designed to address a wide range of applications in chemical and pharmaceutical laboratories. Its robust design and versatile features make it ideal for complex reaction processes that require precise control and observation.

- Link

- Price

- Availability

- Quantity

- GRL-20CE

- 8,830.00€

- 2

-

-

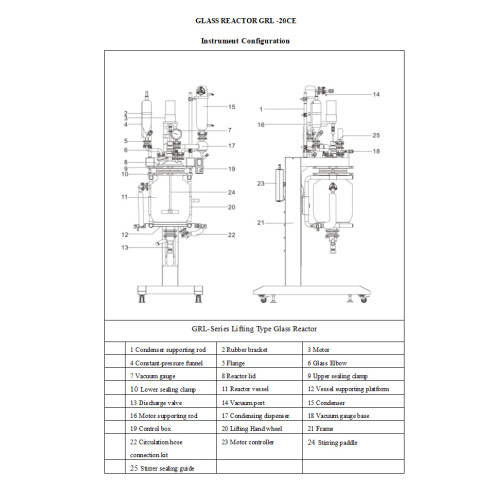

GRL-20CE Glass Reactor: 20-Liter Jacketed Vessel System

You know that point in your project when the 10-liter reactor just isn't cutting it anymore? That's where the GRL-20CE comes in. I've been running this thing for about six months now, and it's become my go-to for anything that needs serious volume without jumping to full pilot scale.

Jacketed Borosilicate Vessel Engineering for 20-Liter Reaction Processes

What you're getting here is 20 liters of working volume in borosilicate 3.3 glass—that's the good stuff with thermal shock resistance up to 200°C differential. The 9-liter jacket capacity isn't just for show either. When you're pushing thermal fluids through at 15-25 L/min, you'll hit thermal equilibration in about 15-20 minutes from ambient. I usually pair mine with the Heating cooling system HR-70 for anything requiring tight temperature control, though the Heater UC-5020 works fine if you're just doing straightforward heating runs.

Temperature Control Through Jacketed Design

- Operating range: -80°C to 200°C with appropriate circulator—you'll need something robust for the low-end work

- Jacket volume: 9L circulation space means fast thermal response, way better than smaller units

- PT100 sensors: Monitor both vessel and jacket temps with ±0.5°C accuracy, which matters when you're doing multi-step syntheses

- Pressure rating: Full vacuum to +0.5 bar gauge with PTFE gasket seals

The overhead stirrer handles 20-500 rpm with ±2 rpm stability. I've run viscous slurries up to 15% solids loading at 200-300 rpm without any issues. The PTFE-coated anchor impeller is your friend for heterogeneous mixtures—just make sure you've got the torque headroom at 150% rated capacity.

Chemical Resistance in Borosilicate 3.3 Construction

Borosilicate 3.3 (DIN ISO 3585 spec) handles pretty much everything you'll throw at it—chlorinated solvents, ethers, aromatics, ketones, esters at operating temps. Chemical inertness across pH 0-14, though you'll want to avoid HF and concentrated alkalis above 80°C. The annealed joints are rated for 10,000+ heating/cooling cycles, and honestly, I believe it. I've been thermal cycling mine constantly and haven't seen any stress cracks yet.

Scalable Synthesis Applications

- Bench-to-pilot transition: Doubles the capacity of smaller units while keeping identical port configs

- Port configuration: 4x GL45 side ports, 1x 100mm top flange, 1x GL25 bottom drain

- Footprint: 840mm W × 1100mm D × 2030mm H, 180kg gross—plan your bench space accordingly

Here's my typical workflow: run the reaction in the GRL-20CE, then transfer directly to the Glass Vacuum Filter CLZZ-20 or CLZZ-30 for filtration under inert atmosphere. From there, filtrates go straight to the Rotary evaporator RE-2000A for solvent recovery. Keeps everything closed-system and saves you from transferring hot reaction mixtures multiple times.

Leave a review about product

Sign up to our newsletter to get the latest news and updates about our products.