Condensers

Laboratory Condensers - Professional Glassware for Distillation and Reflux

Last Tuesday, a postdoc in our organic synthesis lab ran a six-hour reflux without checking his condenser connections. By hour three, solvent vapor was escaping through a loose joint, filling the hood with acetone fumes. That's when I learned that even the best borosilicate glass condensers won't help if you don't match the right design to your process and maintain proper water flow.

Professional Condenser Selection for Distillation and Reflux Operations

Choosing between a straight tube condenser and coiled designs comes down to cooling surface area and your specific application. A straight tube works beautifully for simple distillations with moderate boiling points, while Graham or Allihn types handle higher vapor loads during aggressive reflux operations. I've found that pairing condensers with appropriate glassware matters—using a conical flask with grind ensures leak-proof joints that won't separate under vacuum or pressure changes, unlike threaded connections that can work loose over time.

Cooling Efficiency Across Different Condenser Types

- Liebig condensers: Single straight tube design provides 100-200cm² cooling surface, handles routine distillations up to 150°C

- Graham coil condensers: Spiral inner tube increases surface contact to 300-500cm², excellent for volatile solvents like diethyl ether or dichloromethane

- Allihn bulb condensers: Multiple bulb chambers create turbulent flow, preventing vapor breakthrough during vigorous reflux with low-boiling materials

- Friedrichs designs: Double-walled construction maximizes heat transfer for high-throughput solvent recovery operations

Matching Condensers to Your Application Requirements

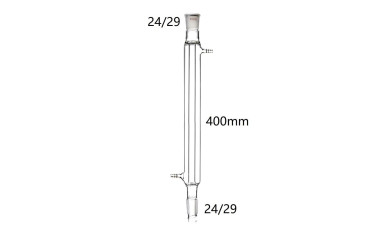

When recovering ethanol from plant extracts, I use a conical flask with a narrow throat as the receiving vessel because it minimizes evaporation losses while the condenser drips product. For fractional distillations requiring precise separation, Vigreux columns with indentations create multiple theoretical plates. Joint size matters more than most people realize—a 24/40 joint on your condenser must match your flask exactly, whether you're using a conical flask with thread and polypropylene cap for storage afterward or transferring directly into laboratory glasses and beakers for analysis. Standard sizes run from 14/20 for microscale work up to 45/50 for pilot-scale preparations.

Water Flow and Temperature Management

Counter-current flow is non-negotiable: water enters at the bottom outlet and exits at the top inlet. I maintain flow rates around 2-3 liters per minute for standard condensers, increasing to 5 L/min during summer when tap water temperatures climb above 20°C. Installing a recirculating chiller keeps coolant at 10-15°C, preventing thermal shock to your glassware while maintaining consistent condensation efficiency throughout marathon synthesis runs.

Our partners

We only work with trusted brands

Sign up to our newsletter to get the latest news and updates about our products.