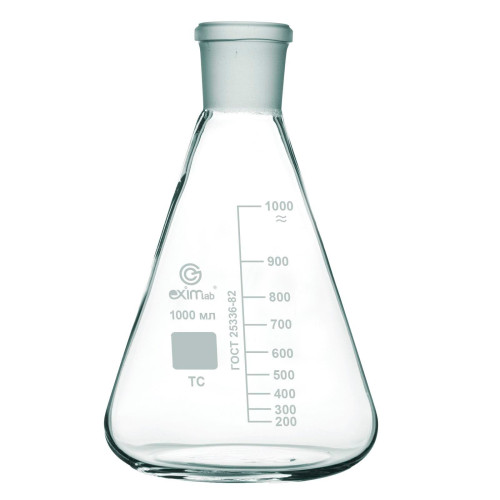

Conical flask with ground section 14/23

Technical Specifications

Material: Borosilicate Glass

Joint Size: 14/23

Capacity: Varies (typically available in 50ml, 100ml, 250ml, 500ml, and 1000ml sizes)

Height: Varies depending on capacity

Diameter: Varies depending on capacity

Temperature Resistance: Up to 500°C

Chemical Resistance: Resistant to most acids and alkalis

available soon

Bench-Scale Sealed Synthesis Using 14/23 Ground Joint Conical Flasks

I've been running these 14/23 ground joint conical flasks for years now, and they've completely changed how I approach sealed reaction setups. You get the stability of a regular Conical flask, narrow neck sitting flat on your stirrer plate, but with proper ground glass connections that actually seal without wrestling with rubber stoppers or parafilm. The 14/23 sizing—that's 14mm inner diameter at the joint with 23mm length—works perfectly for reactions between 50mL and 500mL where you don't need the bulk of larger apparatus.

Borosilicate glass handles everything from liquid nitrogen quenching straight to heating blocks without cracking, and the ground surface creates hermetic seals through precise glass-on-glass contact. What makes these flasks special is how they combine bench-friendly stability with modular joint versatility—you're essentially getting an Erlenmeyer that can connect to condensers, addition funnels, gas inlet adapters, and thermometer wells without any tape or tubing workarounds.

Small-Scale Reaction Advantages with 14/23 Taper Standards

Apply a thin film of high-vacuum grease, insert your male joint component, twist 180 degrees, and you're sealed—no clamps needed for most applications. I run Schlenk line reactions with these all the time because the sealed joint excludes atmospheric moisture completely during air-sensitive organometallic synthesis. Compared to a Boiling Flask,flat bottom where you're dealing with separate stoppers that never quite seal properly, the integrated ground joint eliminates those annoying leak points.

- Liebig condensers mount directly for extended reflux without vapor escape

- Thermometer adapters let you monitor internal temperature with precision

- Gas inlet tubes maintain nitrogen or argon atmosphere throughout reactions

- Pressure-equalizing addition funnels connect for controlled reagent delivery

The smaller joint mass heats and cools faster than 24/40 apparatus, cutting equilibration time when your protocol demands rapid temperature changes. That matters when you're running time-sensitive transformations or working with temperature-labile intermediates. Pharmaceutical development labs use these extensively for parallel synthesis where bench space is premium and you need consistent sealed-system performance.

Conical Shape Benefits for Precipitation and Crystallization

Sloped walls create vortex patterns during magnetic stirring that reach every solution zone—I've never had stratification issues with biphasic extractions in these flasks. The narrow bottom funnels precipitates into minimal dead volume, which really matters when you're recovering expensive catalysts or working with limited starting materials. Compared to a Round Bottom Flask with Ground Joint that needs support rings and multiple clamps eating up fume hood space, conical flasks just sit there and work.

Direct heating block contact provides uniform temperature distribution across the conical surface without hot spots. You get efficient product recovery from the tapered bottom versus the broad-base design of a Flat-Bottom Flask with Joint where material pools in corners. Mark mated joint pairs with matching numbers using a diamond scribe—they wear in together and maintain seal integrity through hundreds of thermal cycles.

- Bench stability means no three-prong clamps required for most setups

- Natural liquid flow guidance during transfers reduces spills and material loss

- Efficient precipitation collection in the narrow conical base

- Better mixing dynamics than cylindrical vessels of equivalent volume

Building Compact Apparatus with Smaller Joint Sizes

The 14/23 scale hits a sweet spot that larger formats just can't match. Multiple flasks fit on multi-position heating blocks without interference—try cramming six 24/40 setups on a single block and you'll run out of space fast. I've screened reaction conditions with six of these running simultaneously for parallel synthesis work, something you simply can't do with bulkier Boiling Flask,round bottom configurations that require elaborate support apparatus.

For Dean-Stark water removal during esterifications or three-neck adapter installations for simultaneous monitoring and reagent addition, the 14/23 scale works beautifully. Clean ground surfaces with acetone between uses and apply grease sparingly to prevent contamination of your reaction mixtures. The flat bottom works directly on stirrer plates, heating mantles, or aluminum blocks without adapters—I've run everything from Grignard additions to catalytic hydrogenations in these flasks, and the sealed joint system gives you confidence that your inert atmosphere stays inert throughout the entire procedure.

Leave a review about product

Sign up to our newsletter to get the latest news and updates about our products.