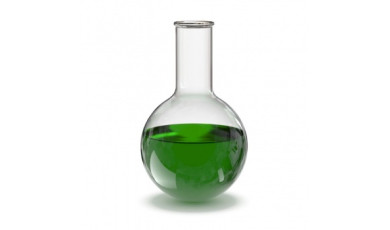

Laboratory boiling flasks

Laboratory Boiling Flasks - Precision Glassware for Thermal Applications

Boiling flasks serve as primary vessels for controlled heating operations where uniform thermal transfer and vapor management are critical. Constructed from Type 1 borosilicate glass conforming to DIN ISO 3585 standards, these flasks handle temperatures reaching 500°C while maintaining structural integrity under rapid thermal cycling. The low expansion coefficient (3.3 × 10⁻⁶ K⁻¹) prevents stress fractures during heating and cooling phases.

Essential Boiling Flask Solutions for Modern Laboratories

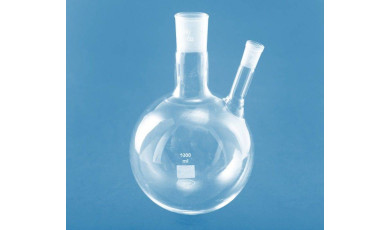

Round-bottom configurations provide optimal heat distribution through continuous curved surfaces, eliminating hot spots that cause localized superheating. Round bottom flask designs work directly with heating mantles, while Round-bottom flask with socket variants integrate ground glass joints (14/20, 19/22, 24/29 sizes) for distillation apparatus assembly. Flat bottom flask options offer freestanding stability on hot plates, though heat transfer efficiency drops approximately 15-20% compared to spherical geometry. For modular setups requiring direct attachment to condensers or addition funnels, Flat Bottom Flask with socket models eliminate the need for separate adapters.

Heat Distribution and Thermal Performance

- Wall thickness uniformity: Maintained at ±0.5mm tolerance prevents differential expansion and thermal stress concentration

- Annealed construction: Post-manufacturing heat treatment removes residual internal stresses that compromise thermal shock resistance

- Neck geometry: Extended narrow necks (typically 150-200mm length) reduce vapor loss rates by 40-60% during reflux operations

- Surface area ratios: Round-bottom designs maximize liquid contact with heat source while minimizing exposed surface for evaporation control

Material Composition and Chemical Resistance

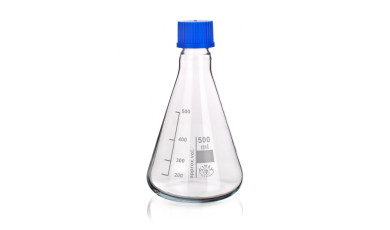

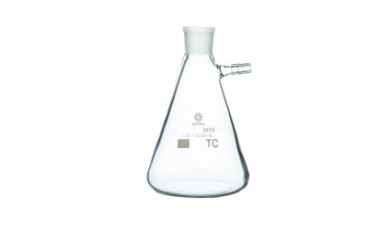

Borosilicate glass composition (81% SiO₂, 13% B₂O₃, 4% Na₂O) provides resistance to strong acids, alkalis, and organic solvents across pH ranges 0-14. Hydrofluoric acid and hot concentrated phosphoric acid remain exceptions requiring PTFE vessels. The non-porous surface prevents analyte absorption, critical for trace analysis work. Unlike Conical flask with a wide throat designs optimized for mixing and culture work, boiling flasks prioritize sealed environments with minimal headspace for controlled vapor-phase reactions.

Volume Capacities and Size Selection

Standard capacities span 25ml through 5000ml, with working volumes recommended at 50-70% of total capacity to prevent boil-over during vigorous heating. Graduated variants feature ±5% volume accuracy for approximate measurements, while non-graduated models eliminate potential contamination sites in etched markings. Select neck diameter based on stopper size requirements: 10/19 joints for micro-scale work (25-100ml), 24/29 for general applications (250-1000ml), and 29/32 for preparative-scale operations (2000ml+).

Our partners